The Lexan Thermoclear multiwall sheet is a high quality, low maintenance glazing material based on Lexan polycarbonate resin. It features a two-sided proprietary surface treatment that is designed to protect the sheet against the degrading effects of ultra-violet radiation in natural sunlight, yellowing and ultimately, protection against Australia’s harsh climate.

Certified under Australian Standards, the sheets cost less and have higher impact strength than glass. Installation mistakes are furthermore minimised as both sides of the sheet surfaces are UV protected and may be faced outwards.

“Key advantages include good thermal performance, small cost compared to glass, light weight long spans meaning less structure, and very high impact resistance,” says architectural representative at Ampelite, Anthony Milicic.

“One major key advantage incorporating all others is its versatility to provide natural light. Architects and designers can use the Lexan multiwall products as skylights, wall lights, cladding, partitioning, pergolas and awnings, to name a few.”

This versatility opens the product up to a wide realm of commercial, industrial and residential applications – from conservatories, commercial greenhouse and swimming pools, to industrial buildings, offices, homes and sports stadiums.

Other features of the Lexan Polycarbonate Sheet include high wind resistance, and a fire rating that conforms to Australian Standard 1530.3:2006 (a test standard describing methods for fire tests on building materials and structures according to their tendency to ignite, propagate flame, release smoke, and the amount of heat release once ignition has occurred).

Lexan Thermoclear multiwall sheet can also be cold-formed into tight radii without pre-forming, allowing for curved glazing, and easily cut to a desired length or width.

Lightweight and durable, the sheet’s flat structure allows for the use of aluminium glazing bar systems which ensures a long-lasting performance.

In terms of contributing to a building’s energy efficiency, the multiwall construction traps air between its layers, ensuring good thermal insulation performances and helping users save on both air conditioning and heating costs. It can resist temperature impacts from 40°C to + 120°C.

Moreover, new technology, whereby proprietary resin additives have been used to block near-infrared heat while maintaining high levels of light transmission, helps with heat management and stabilising indoor temperatures. According to Ampelite, studies have shown that this can result in energy savings of 25-40 per cent in a temperature controlled environment.

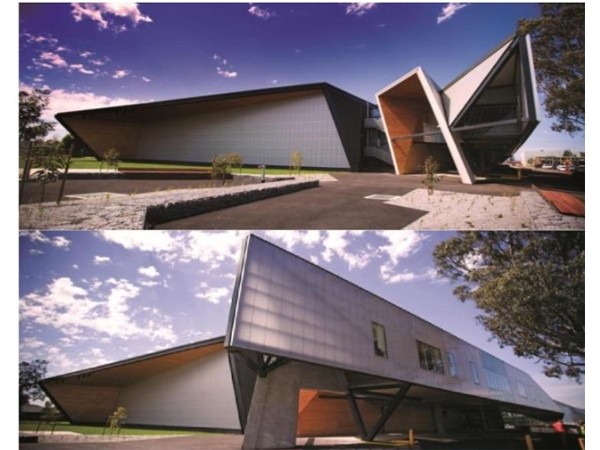

CASE STUDY: VICTORIA UNIVERSITY BY COX ARCHITECTS

Lexan Thermoclear has been utilised at the $44 million Construction Futures project at Victoria University in Melbourne by Cox Architects.

Completed in late 2012 by Kane Constructions, the 12,000m2 facility provides a campus that delivers construction and building trainings.

According to Ampelite, incorporating the Lexan Thermoclear sheets in the design has helped express the progressive nature of the construction industry, specifically the influx of new materials and construction design technologies that are readily available and rapidly developed. This will encourage industry partners to engage with the centre, providing the students with invaluable experience and industry exposure.

The project has since been certified with a 6 Star Green Star - Education V1 design rating with the GBCA.